Understanding Compression Springs: Design, Applications, and Troubleshooting

Compression springs are essential components in countless mechanical devices, from automotive suspension systems to industrial machinery. By absorbing, storing, and releasing energy, these helical coils provide the necessary force to push or pull components together. In this comprehensive guide, we'll explore the design considerations, common applications, and troubleshooting tips for compression springs.

Compression spring design

Careful consideration of these design factors is crucial to ensure the spring performs reliably and meets the specific application requirements. Consulting with experienced spring manufacturers like Xinzhaolang can help optimize your compression spring design.

The versatility of compression springs lies in their ability to handle substantial loads and stresses repeatedly without permanent deformation. However, proper material selection and design are essential to ensure reliable performance in each unique application.

Regular inspection and maintenance, along with proper installation and use within the designed load capacity, can help prevent premature compression spring failures. If a failure does occur, a thorough analysis of the operating conditions and spring design can identify the root cause and guide improvements.

For high-quality, custom compression springs tailored to your specific application needs, consider partnering with a reputable and professional spring manufacturer. With extensive experience in spring design and manufacturing, Xinzhaolang can help you achieve optimal results for your project.

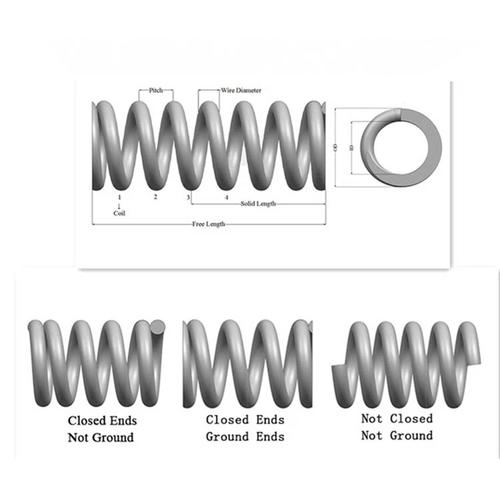

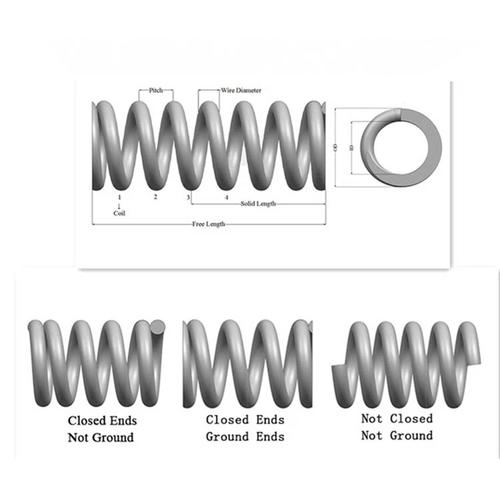

Compression Spring Design

Several key factors influence the performance and reliability of compression springs:- Material selection: Common materials include steel alloys, stainless steel, and chrome vanadium, each offering different advantages in terms of strength, corrosion resistance, and temperature tolerance.

- Spring rate: The spring rate, measured in pounds per inch (lb/in), determines the load capacity. A higher spring rate means the spring can handle greater loads.

- Dimensional limits: The allowable solid height and outside/inside diameters govern the stress level and proper functioning of the spring within the allotted space.

- Number of coils: More coils generally result in a stronger spring, but designers must balance this with the desired spring rate and dimensional constraints.

Compression spring design

Careful consideration of these design factors is crucial to ensure the spring performs reliably and meets the specific application requirements. Consulting with experienced spring manufacturers like Xinzhaolang can help optimize your compression spring design.

Applications of Compression Springs

Compression springs find use in a wide range of industries and applications:- Automotive: In suspension systems, valve trains, and transmission assemblies

- Aerospace: In landing gear, engine mounts, and actuation systems

- Medical devices: In surgical instruments, drug delivery mechanisms, and rehabilitation equipment

- Industrial machinery: In valves, actuators, clutches, and brakes

Troubleshooting Compression Spring Failures

Despite their reliability, compression springs can fail prematurely due to various factors:- Overloading: Subjecting the spring to loads beyond its designed capacity can lead to permanent deformation or breakage.

- Fatigue: Repeated stress cycles can cause fatigue failure, especially if the spring is not designed for the expected number of cycles.

- Corrosion: Exposure to corrosive environments, such as high humidity or chemical fumes, can weaken the spring material and lead to failure.

- Improper installation: Misalignment or incorrect preload can cause uneven stress distribution and premature failure.

Conclusion

Compression springs play a vital role in countless mechanical applications, providing the necessary force and energy storage to ensure smooth operation. By understanding the key design considerations, common applications, and potential failure modes, engineers and manufacturers can optimize compression spring performance and reliability.For high-quality, custom compression springs tailored to your specific application needs, consider partnering with a reputable and professional spring manufacturer. With extensive experience in spring design and manufacturing, Xinzhaolang can help you achieve optimal results for your project.