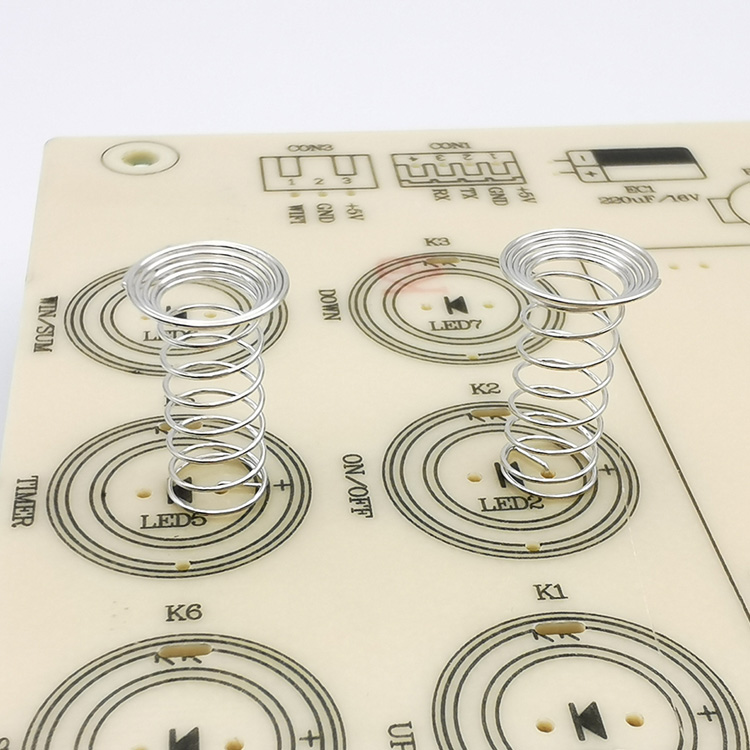

Reinforced Music Wire Compression Springs: Built to Last Under Pressure

In the realm of spring manufacturing, music wire compression springs stand out as a vital component, especially in musical instruments and various industrial applications. Renowned for their durability and resilience, these springs are crafted from high-carbon steel, making them ideal for environments where they must endure significant stress and repeated use. This article delves into the properties, advantages, and applications of music wire compression springs, highlighting why they are an excellent choice for custom spring solutions.

Understanding Music Wire Compression Springs

Music wire is a type of high-carbon steel wire known for its exceptional tensile strength and elasticity. Its name derives from its historical use in musical instruments, particularly pianos, where it was used to create strings capable of withstanding high tension while producing clear tones. Today, music wire is widely utilized in the production of compression springs due to its unique properties.

Key Properties of Music Wire Compression Springs

High Tensile Strength: Music wire compression springs can handle substantial loads without permanent deformation. This characteristic is crucial in applications where springs must return to their original shape after being compressed.

Elasticity: The inherent elasticity of music wire allows these springs to compress and extend efficiently, making them suitable for various mechanical applications.

Fatigue Resistance: Designed to endure thousands of cycles, music wire springs maintain their performance over time, making them ideal for repetitive motion applications.

Heat Resistance: These springs can withstand elevated temperatures up to 250°F (121°C) without compromising their structural integrity, which is essential in many industrial settings.

Cost-Effectiveness: Compared to other high-performance materials, music wire is relatively affordable, making it an economical choice for manufacturers looking for quality without breaking the bank.

Applications of Music Wire Compression Springs

Music wire compression springs are utilized across multiple industries due to their reliability and performance. Here are some key applications:

Musical Instruments: As the primary application, these springs are crucial in pianos and guitars. In pianos, they support key mechanisms that ensure keys return to their original position after being pressed. In electric guitars, music wire compression springs balance the tension created by the strings in tremolo systems, allowing smooth pitch modulation.

Automotive Industry: Music wire compression springs are used in various automotive components, such as suspension systems and engine parts where durability under pressure is essential.

Industrial Machinery: These springs play a critical role in machinery that requires consistent force application, such as presses and conveyors. Their ability to withstand heavy loads makes them suitable for high-stress environments.

Consumer Products: Everyday items like pens and toys often incorporate music wire compression springs due to their long-lasting performance and reliability.

Advantages of Choosing Music Wire Compression Springs

When selecting springs for specific applications, several advantages make music wire compression springs a preferred choice:

Versatility: The design flexibility of music wire allows manufacturers to create custom solutions tailored to specific needs. This adaptability is crucial for industries requiring specialized spring configurations.

Performance Under Stress: Music wire's ability to handle high-stress situations without failure ensures that products remain functional over time, reducing maintenance costs and downtime.

Ease of Manufacturing: The processes involved in producing music wire compression springs are well-established, allowing for efficient mass production while maintaining quality standards.

Corrosion Resistance Options: While music wire itself is not inherently corrosion-resistant, manufacturers can apply coatings such as zinc plating to enhance durability against environmental factors.

Conclusion

In summary, music wire compression springs are built to last under pressure, making them indispensable across various industries. Their unique properties—high tensile strength, elasticity, fatigue resistance, and heat tolerance—ensure reliable performance in demanding applications. Whether used in musical instruments or industrial machinery, these springs offer a cost-effective solution for manufacturers seeking durable spring solutions.

At Xinzhaolang, we specialize in providing custom spring solutions tailored to your specific needs. Our expertise in manufacturing high-quality music wire compression springs ensures that you receive products designed for optimal performance and longevity. Contact us today to learn more about how our spring solutions can enhance your products and drive inquiry conversions!