Why And How To Choose Rectangular Wire Compression Springs?

Rectangular wire compression springs, an essential component of various mechanical systems, play a pivotal role in ensuring smooth operations. They are precision-engineered, often underestimated, yet indispensable elements of machinery across various industries.

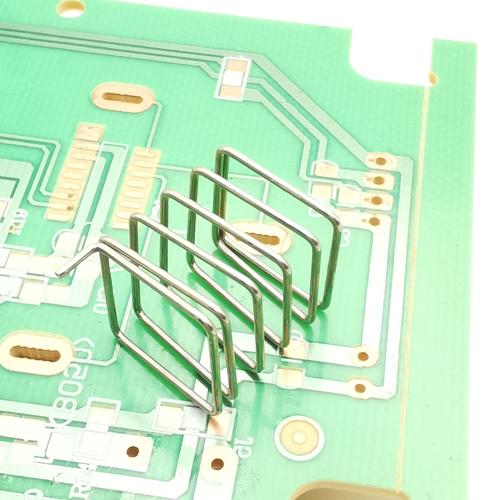

Overviews Of Rectangular Wire Compression Springs

Rectangular wire compression springs are mechanical devices that store and release energy when subjected to a compressive force. Unlike their more common cylindrical counterparts, these springs are shaped from rectangular wire, providing unique advantages in certain applications. Their design imparts specific performance characteristics that make them highly sought after in various industries.

These springs find extensive use in numerous applications, from automotive suspension systems to medical devices. The rectangular wire configuration allows for efficient energy storage and release, making them indispensable in scenarios where space is a critical constraint. The importance of these springs cannot be understated, as they contribute to the stability and functionality of countless mechanical systems.

Rectangular wire compression springs offer distinct advantages, such as reduced solid height, increased lateral stability, and higher energy storage capacity. Their unique shape allows them to fit into tight spaces without compromising performance. These features make them a versatile choice in situations where cylindrical springs may not be as effective.

Design and Manufacturing

Materials Selection

The performance of rectangular wire compression springs is closely tied to the materials used in their construction. Manufacturers often select high-quality alloys, including chrome silicon and stainless steel, to ensure durability and resistance to corrosion. The material choice depends on the specific requirements of the application.

Manufacturing Process

The manufacturing of these springs involves precision engineering. The rectangular wire is carefully coiled and formed to exact specifications. Advanced machinery ensures consistent spring geometry, which is crucial for reliable performance. The coiling process, coupled with stress relief treatments, enhances the spring's longevity and fatigue resistance.

Design Considerations

Designing rectangular wire compression springs demands a deep understanding of the application's requirements. Factors like load capacity, deflection, and environmental conditions play a vital role in determining the spring's design parameters. Engineers must also consider the spring's solid height and the available space for installation, which are often critical in real-world applications.

Performance and Characteristics

Load-Carrying Capacity

Rectangular wire compression springs excel in carrying substantial loads while maintaining their spring rate. The unique wire shape and manufacturing precision allow them to withstand compression while providing predictable and consistent performance.

Spring Rate and Stiffness

These springs exhibit excellent spring rates and stiffness, making them suitable for applications where controlled deflection and resistance to variable loads are essential. Their rectangular shape provides lateral support, reducing the chances of buckling under extreme loads.

Fatigue Resistance

The rectangular wire construction, along with stress relief treatments, contributes to impressive fatigue resistance. These springs can endure cyclic loading for extended periods, ensuring reliability and longevity in demanding applications.

Use Cases and Industry Applications

Automotive Industry

In the automotive sector, rectangular wire compression springs are utilized in suspension systems. Their ability to efficiently store and release energy helps provide a smooth and stable ride. This application showcases their value in a highly dynamic and safety-critical environment.

Aerospace Industry

Aerospace applications benefit from the compact design of rectangular wire compression springs. They are used in landing gear and control systems, where weight and space constraints are paramount. The reliability and durability of these springs are particularly valuable in this industry.

Medical Devices

Medical devices, including implantable and diagnostic equipment, rely on the precision of these springs. Their consistent performance and corrosion resistance are crucial in medical applications where patient safety is non-negotiable.

Other Sectors

Beyond the mentioned industries, rectangular wire compression springs find utility in various other sectors, including electronics, robotics, and industrial machinery. Their unique design allows for tailored solutions to meet specific application demands.

Conclusion

Rectangular wire compression springs offer a tailored solution to various industries seeking reliable, space-efficient, and durable energy storage and release mechanisms. Their unique design, coupled with precise engineering and materials selection, makes them indispensable components in a wide array of mechanical systems, contributing to efficiency, safety, and performance across industries.